The Rears 600-Series Pak-Flail Mower sets the industry standard for commercial mowing. As the latest evolution

in our heavy-duty mower line, the 600-Series has been perfected over 75 years, reflecting our commitment to

increasing durability through continuous improvement

The 600-Series Mowers are available in widths from 6'-15' (Cutting Swath). This product line has many available

blade options and add-ons which are discussed below.

.png)

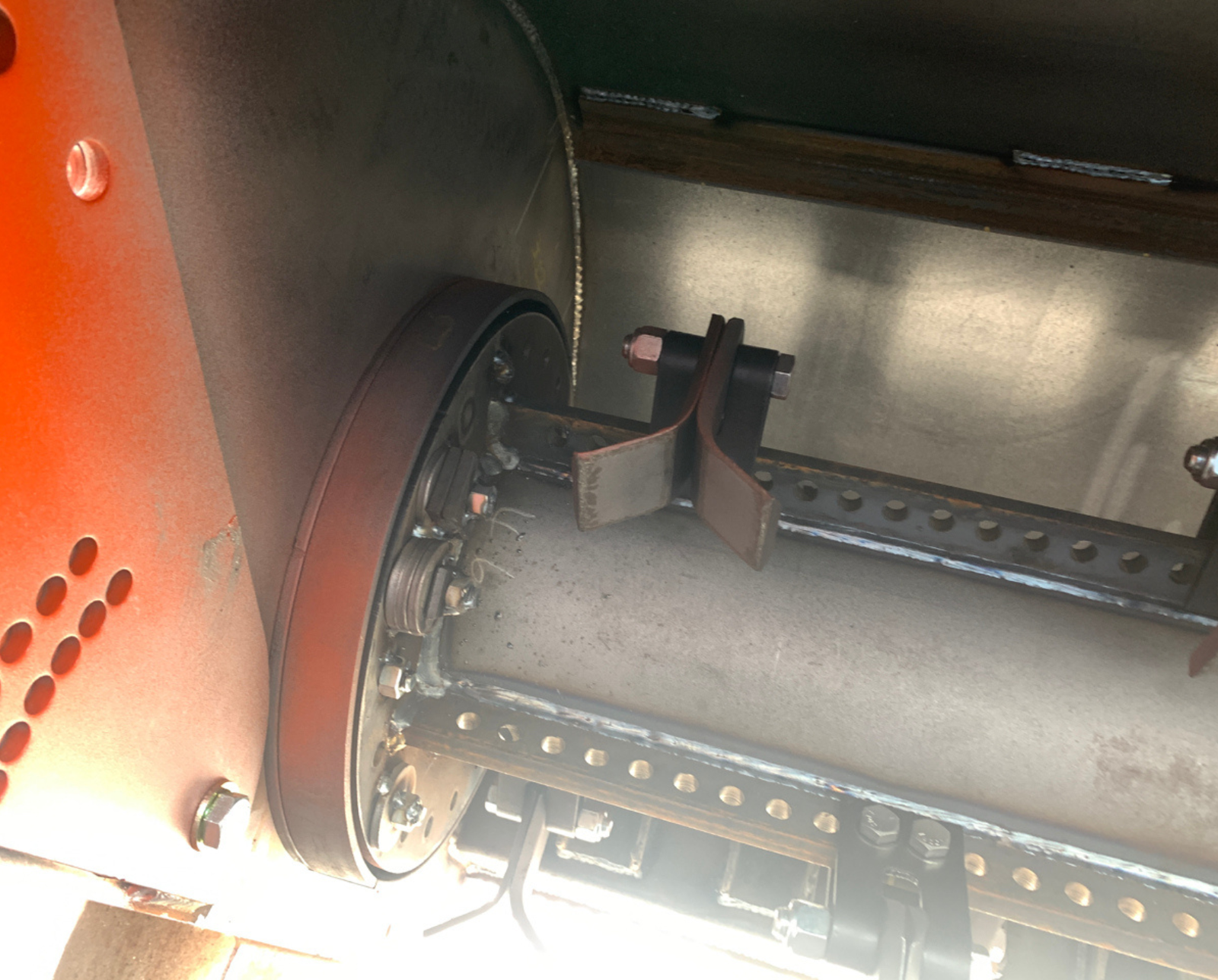

Rears 600-Series mowers are built with a robust 3/16" A36 Mild Steel Housing. Known for its reliability, the A36 material has a Brinell hardness of 150 and has stood the test of time, offering excellent wear resistance at an economical price.

The AR400 Hardened Alloy housing demonstrates superior performance with a Brinell hardness of 400. AR400 steel, used in constructing quarry loader buckets, has shown to triple the work life over high-strength T-1 steel.

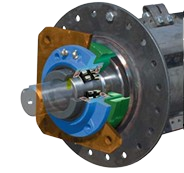

Our self-aligning double spherical FLMB500 roller bearing is a top-tier performer, specifically designed for handling heavy loads and impact deflection.

This rotor bearing demonstrates unmatched durability and reliability.

To protect the bearing from the harsh environment inside the flail, the engineers at Rears developed an integrated grease

labyrinth barrier within the rotor mandrel. This barrier provides maximum protection and effectively isolates the bearing.

The design ensures that over-greasing is no longer a concern, as all excess lubricant is vented into the renewable labyrinth, thus purging

any impurities that have been introduced during operation. This grease labyrinth also helps to keep the bearing cool under load.

The Rears triple-sealed roller bearing is designed with anti-wrap protection, ensuring reliable performance and longevity. The pilot ring on the bearing housing is precisely mounted into a machined slot in the roller pivot plate. This piloted steel joint, rather than the bearing mount bolts, bears the weight of the flail, providing exceptional stability and durability. Adjusting your machine's cut height is straightforward. Simply rotate the pivot plate to achieve the desired position.

.png)

The upright belt housing is the standard for the 600-Series Mower. Upright belt housings meausure 37-1/4". The upright belt housing is perfect for applications where overall flail height is not an issue (i.e. pasture mowing, offset flail mowing)

The low profile belt housing rocks the belt housing backwards and down to help avoid flail interference with fruit / canopy. The low-profile belt housing measures Low Profile: 28-1/4". The low profile belt housing is used commonly in vineyard & orchard applications.

A36 3/16" mild steel weld-in liner. This option lines the interior of the flail housing with a mild steel liner that is welded in at our facility. This is an economical option for a customer who won't mind cutting the liner out and replacing it at a later time.

The A36 bolt-in liner option is a 3/16" mild steel liner that is bolted into the flail housing. This option is cheaper than the AR liner option while allowing for greater ease in replacement + installation than the weld-in liner options.

The AR400 weld-in liner option is a 3/16" AR400 that is welded into the flail housing. This is our premium heavy duty Liner built for customers who plan to put the hours on their machines. AR400 measures 400 on the Brinell scale (A36 Measures 150)

The AR400 Bolt-in liner option is a 3/16" AR400 that is bolted into the flail housing. This is our premium heavy duty Liner built for customers who plan to put the hours on their machines. AR400 measures 400 on the Brinell scale (A36 Measures 150). The bolt-in liner allows for greater ease in replacement + installation than the weld-in liner options.

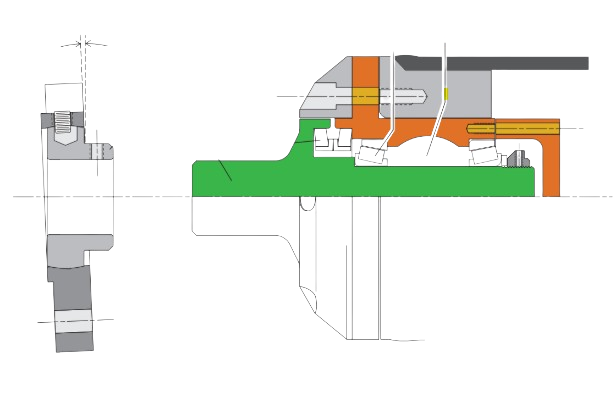

Upgrading to an optional shredder package is a savvy move when you need that enhanced shred quality. The full-length angle shearbar and hard-surfaced shear channels aren't just fancy add-ons—they're game changers. By impacting small prunings and leaves, they grind material down into much finer particulates, which can significantly improve decomposition rates.

.jpg)

Rotating Axle cut height adjustment utilizing hydraulic cylinder available upon request. Single & dual struts are available (along with different wheel and tire assemblies depending on application/ground conditions). If turning without picking up the machine is a requirement, then castering gauge wheels will be required.

.jpeg)

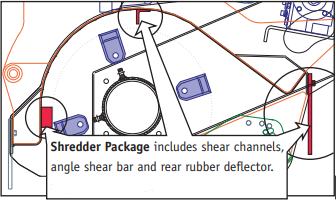

| Specification Sheet | |||

|---|---|---|---|

| Cutting Width | 6' - 15' | ||

| Overall Width | 12" Over Cutting Width | ||

| 3-PT | Category II Free-Link (Fixed or Centermount) | ||

| Horsepower Requirement | 5-6 Horsepower/ft Depending on Loading Scenarios (Ground Speed / Terrain / Biomass) |

||

| 6'-13' Swath | 14'-15' Swath | ||

| Rotor Mandrel | 2-7/16" Shaft 8-5/8" Mandrel |

2-7/16" Shaft 10-5/8" Mandrel |

|

| Knife Tip Speed | 10,200 FPM | 9,830 FPM | |

| Mandrel Speed | 1,730 RPM | 1,520 RPM | |

| Belt Housing Height | Upright: 37-1/4" Low Profile: 28-1/4" |

Low Profile: 29-5/16" | |

| Flail Housing Height | 25-1/2" | 27-15/16" | |

| Weight, STD. Unit (Opt. Dependent) | 6': 1,800lbs 8': 2,000lbs 10': 2,200lbs 12': 2,400lbs |

14': 2,950lbs 15': 3,150lbs |

|

| 6'-12' Swath | 13'-15' Swath | ||

| Blades | FL920 FL960 FL946 |

FL920 FL960 |

|

| Gauge Roller | 1-3/4" Shaft, 8-5/8"Ø Roller | ||

| Cut Height | 0" (Scalping) - 5" | ||

.png)