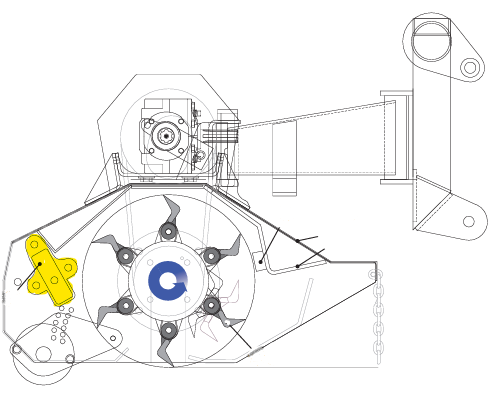

The OMF orchard shredder combines a low-profile design with exceptional functionality, making it ideal for operating

under low tree skirting. Equipped with cutting-edge cutter drums featuring variably spaced clevis pads and blade or

hammer assemblies, it ensures a smooth, efficient, and precise cutting performance for shredding orchard brush.

Each unit is built with a versatile, multi-position rear deflector door, designed to retain material in the

cutting path for optimal shredding. The OMF models incorporate our reliable belt tensioning system, while the rotor

and roller bearings are safeguarded from even the harshest environments by our advanced labyrinth greasing system.

The OMF shredder sets the standard for durability and performance

The OMF Shredders are used primarily in vineyards and apple and cherry orchards where overall width

is a concern. The OMF is equipped standard with a hydraulic pantograph offset, enabling the shredder to operate

closer to the plantings while maintaining a safe distance for the tractor. The OMF is available with an upright

and vineyard (Low Profile) belt housing for particularly dense plantings/canopy.

The OM750 hammer is Specifically Designed for Shredding Brush. This hammer (in conjunction with the OMF recycling door) pulverizes wood efficiently.

Standard on our field choppers, the crop-chop knife is rolled to shape from C1050 alloy steel and heat treated for long edge life. The FL946 will shred light prunings while still being able to mow cover crop.

Floating brush rakes assist with feeding material into rotor swing line for better shred quality and coverage. Rake height is adjustable using simple bolt and stop mechanism.

Our self-aligning double spherical FLMB500 roller bearing is a top-tier performer, specifically designed for handling heavy loads and impact deflection.

This rotor bearing demonstrates unmatched durability and reliability.

To protect the bearing from the harsh environment inside the flail, the engineers at Rears developed an integrated grease

labyrinth barrier within the rotor mandrel. This barrier provides maximum protection and effectively isolates the bearing.

The design ensures that over-greasing is no longer a concern, as all excess lubricant is vented into the renewable labyrinth, thus purging

any impurities that have been introduced during operation. This grease labyrinth also helps to keep the bearing cool under load.

The Rears triple-sealed roller bearing is designed with anti-wrap protection, ensuring reliable performance and longevity. The pilot ring on the bearing housing is precisely mounted into a machined slot in the roller pivot plate. This piloted steel joint, rather than the bearing mount bolts, bears the weight of the flail, providing exceptional stability and durability. Adjusting your machine's cut height is straightforward. Simply rotate the pivot plate to achieve the desired position.

The upright belt housing is the standard for the IFA. Upright belt housings meausure 30-7/8" for units under 85" (cutting swath) and 33-1/8" for units over 84". The upright belt housing is perfect for applications where overall flail height is not an issue (i.e. pasture mowing, offset flail mowing)

The vineyard profile belt housing rocks the belt housing forward and down to help avoid flail interference with fruit / canopy and to assist with driveline angle issues that arise from low PTO heights in small orchard tractors. The vineyard profile belt housing measures 25-7/8" (Cutting Swath) and 24-3/4" for units over 84". The vineyard housing is used commonly in vineyard & orchard applications.

Standard rotor rotation is opposite the direction of the tractor tire. This rotation may be reversed for Roadside Applications where Material Discharge is Hazardous.

The OMF Shredders are available in a push-pull configuration, allowing them to be mounted at the front or rear of a tractor. Tractor make and model plays a signficant role in whether a push-pull model will be a good fit. Compatibility will depend on front lift-arm length, tractor front PTO speed (540 vs 1000RPM), and tractor PTO shaft (1-3/8" 6-Spline vs 1-3/8" 21-Spline).

The OMF Shredders are equipped with a 3-position deflector door, designed to keep material in the

flail swing line until it has been pulverized enough to leave the housing.

The recycling door drastically increase horsepower requirements while increasing shred quality.

The door's position can be adjusted to optimize your needs between ground speed and desired shred

quality.

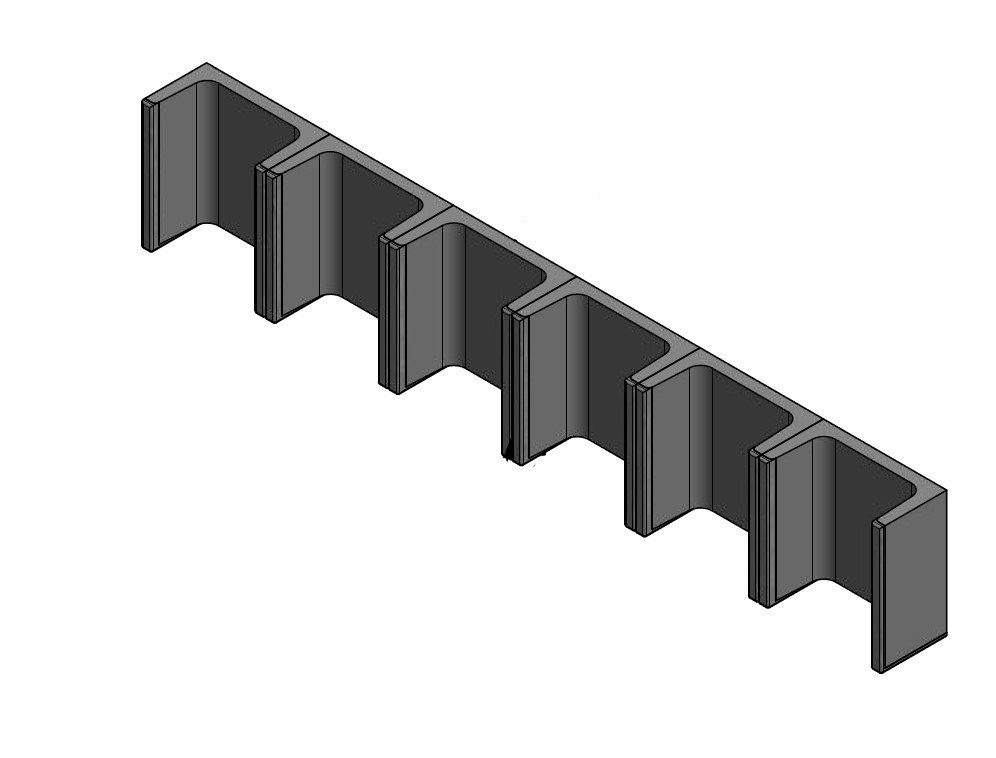

Shear channels are welded along the full length of the OMF housing to provide a hardened surface

for material to shred against. These shear channels are hard surfaced for longevity and contribute

significantly to increased overall material shred quality.

.jpg)

Tie tube style gauge wheels with bolt unbolt pivot for cut height adjustment. If turning without picking up the machine is a requirement, then castering gauge wheels will be required.

| Specification | ||||

|---|---|---|---|---|

| Cutting Width | 48" - 120" | |||

| Overall Width | 6" Over Cutting Width | |||

| 3-PT | Category I & II Freelink Cat. I & II Standardbr> Quick Hitch Compatibility on Request |

|||

| Horsepower Requirement | 5-6 Horsepower/ft Depending on Loading Scenarios (Ground Speed / Terrain / Biomass) |

|||

| FL920 / FL960 | FL946 | |||

| Rotor Mandrel | 1-15/16" Shaft Mandrel: 72" and Below: 5" >73": 6" |

1-15/16" Shaft Mandrel: 6" (Pad Rotor) |

||

| Mandrel Speed | 2,400 RPM | |||

| Blade Tip Speed | 72" and Below: 5" Mandrel / 11,300 FPM >72": 6" Mandrel / 12,250 FPM |

All Sizes: 6" Mandrel / 11,500 FPM | ||

| Weight, STD. Unit (Opt. Dependent) | 30": 550lbs 48": 625lbs 72": 755lbs 84: 885lbs |

|||

| 48"-84" Swath | 84"-120" Swath | |||

| Belt Housing Height | 30-7/8" | 33-1/8" | ||

| Flail Housing Height | 20-3/4" | 21-3/4" | ||

| Blades | FL920 FL960 FL946 |

FL920 FL960 |

||

| Gauge Roller | 1-3/4" Shaft, 6-5/8"Ø Roller | |||

| Cut Height | 0" (Scalping) - 5" | |||

| Specification | ||||

|---|---|---|---|---|

| Cutting Width | 48" - 120" | |||

| Overall Width | 6" Over Cutting Width | |||

| 3-PT | Category I & II Freelink Cat. I & II Standardbr> Quick Hitch Compatibility on Request |

|||

| Horsepower Requirement | 5-6 Horsepower/ft Depending on Loading Scenarios (Ground Speed / Terrain / Biomass) |

|||

| FL920 / FL960 | FL946 | |||

| Rotor Mandrel | 1-15/16" Shaft Mandrel: 72" and Below: 5" >73": 6" |

1-15/16" Shaft Mandrel: 6" (Pad Rotor) |

||

| Mandrel Speed | 2,400 RPM | |||

| Blade Tip Speed | 72" and Below: 5" Mandrel / 11,300 FPM >72": 6" Mandrel / 12,250 FPM |

All Sizes: 6" Mandrel / 11,500 FPM | ||

| Weight, STD. Unit (Opt. Dependent) | 30": 550lbs 48": 625lbs 72": 755lbs 84: 885lbs |

|||

| 48"-84" Swath | 84"-120" Swath | |||

| Belt Housing Height | 23-1/4" | 23-1/4" | ||

| Flail Housing Height | 20-3/4" | 21-3/4" | ||

| Blades | FL920 FL960 FL946 |

FL920 FL960 |

||

| Gauge Roller | 1-3/4" Shaft, 6-5/8"Ø Roller | |||

| Cut Height | 0" (Scalping) - 5" | |||