The 800-Series Chopper is engineered for exceptional durability, featuring rolled inner and outer housing panels reinforced with full-width

front and rear torsion pipes for a highly rigid frame. Its wide in-feed mouth efficiently handles large volumes of material.

The 800-Series chopper is the premier high-horsepower field mowing chopper on the market. This series is built to hold up in rice, mustard, and other

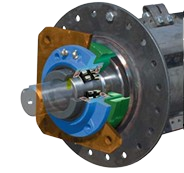

arduous applications. The heavy-duty 2-7/16" mandrel bearings are equipped with a reliable grease labyrinth system, ensuring robust protection and extended service life. For

enhanced shredding, the optional rear recycling door allows for additional material processing. Widths from 7' to 22' are available. Any width

12' or greater will have a center bearing that will leave an uncut strip. This center bearing can be moved up to 30" to put at center of furrow

or a center strip eliminator option can be installed to mitigate this uncut strip.

The 800-Series is heavier duty than the S-Series chopper in a number of ways. This includes higher horsepower rated gearbox, input driveline, jackshaft

drivelines, and belt drive.

Available options include:

Standard on our field choppers, the crop-chop knife is rolled to shape from C1050 alloy steel and heat treated for long edge life. Both the FL940 and 946 are reversible- the FL946 is a hard surfaced knife.

The Rears 800-Series Pak Chopper connects directly to the tractor 3-Point or the tractor quick hitch. This style typically utilizes castering gauge wheels on the rear axle to allow the customer to perform cutting turns while shredding field crops or navigating a duck club. Cut height adjustment is performed utilizing a rotating axle.

The Rears 800-Series Pul Chopper utilizes either the Rears Constant Velocity Hitch (See CV Hitch Below) or a drawbar hitch. These units are commonly utilized in row crop applications, where the fixed single struts can be moved and clamped to be in line with furrows. Cut height is modulated using a rotating axle (hydraulic cylinder actuated).

.jpg)

Our self-aligning double spherical FLMB500 roller bearing is a top-tier performer, specifically designed for handling heavy loads and impact deflection.

This rotor bearing demonstrates unmatched durability and reliability.

To protect the bearing from the harsh environment inside the flail, the engineers at Rears developed an integrated grease

labyrinth barrier within the rotor mandrel. This barrier provides maximum protection and effectively isolates the bearing.

The design ensures that over-greasing is no longer a concern, as all excess lubricant is vented into the renewable labyrinth, thus purging

any impurities that have been introduced during operation. This grease labyrinth also helps to keep the bearing cool under load.

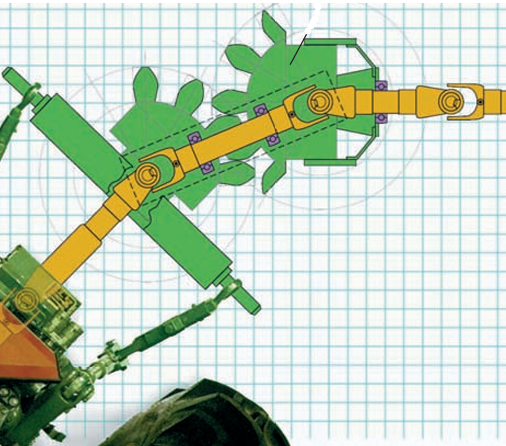

Rears Shredders utilize our Constant Velocity Hitch

for superior tracking: keep on running through 90° turns. Telescoping driveline eliminated protects tractor PTO

Utilizes the tractor 3-point hitch removes the requirement to establish a hitch pin center point

Our Constant Velocity Hitch offers several advantages over a CV Driveline:

Smooth Power Transfer: It ensures uniform rotational speed, even when the tractor and

implement are at different angles, reducing vibrations and noise.

Flexibility: It allows for efficient operation during sharp turns or uneven terrain,

maintaining consistent performance.

Durability: These hitches are designed to handle high torque loads and are very robust. CV hitches

do NOT utilize a CV driveline (which may be expensive and difficult to maintain).

Reduced Wear and Tear: By minimizing vibrations and shocks, it helps extend the lifespan of connected machinery.

All 800-Series Choppers are equipped with 3" shear channels. The blades of the rotor swing material between these shear channels, resulting in increased shred quality. These shear channels are mount on 12" centers. These is also an angle shearbar welded inside the housing to further increase shred quality.

| Specification | |||

|---|---|---|---|

| Cutting Width | 7' - 22' | ||

| Overall Width |

Single Drive: 12" Over Cutting Width Dual Drive: 24" Over Cutting Width |

||

| 3-PT | Category II Freelink Cat. II Standard, Cat III & Quick Hitch Compatibilty on Request |

||

| Horsepower Requirement | 10-15 Horsepower/ft Depending on Loading Scenarios (Ground Speed / Terrain / Biomass) |

||

| Hammer Type | FL946 | FL953 | |

| Rotor Mandrel | 2-7/16" Mandrel:8-5/8" |

||

| Mandrel Speed | 1720-2100 (Crop / FCP Dependent) | ||

| Blade Tip Speed | FCP Dependent | ||

| Weight, STD. Unit (Opt. Dependent) | 7': 6,000lbs 8' 6,200lbs 9': 6,400lbs Weight Depends Greatly on Options Chosen | ||

| Gearbox Rating | 85 Horsepower | ||

| Belt Drive | Single Drive: 5-Groove, 5VX Belt Drive | Dual Drive: 4-Groove, 5VX Belt Drive | |

| Flail Housing | Double Housing, 3/16" Steel. Liners Available. | ||

| Hydraulics | Requires one Set of Tractor Remotes | ||

| Input Driveline | Category VI | ||

| Cut Height | Scalping (0") - 6" (Call if needed Outside Range) | ||

.jpg)