The high-performance brush shredder is engineered for durability and efficiency, featuring a 108” cutting width

and John Deere 6090 Power Tech® 400hp engine to tackle demanding brush-clearing applications. Built with a heavy-duty

housing, reinforced rotor system, and hydraulic-driven feed rolls, this shredder excels at processing tough vegetation

while minimizing maintenance. The dual-speed bottom feed roll and replaceable tungsten carbide hammers ensure maximum

shredding power. Equipped with adjustable cutting height, electric braking options, and a high-clearance hitch, this

shredder is designed for reliability

This machine is the premier orchard shredder with a sizing screen designed to regulate the final material output size.

It functions by filtering shredded material, ensuring only appropriately sized pieces exit the machine while larger

fragments are retained for further processing. This machine is ideal for ground-harvested nut applications where

residual small brush is unacceptable.

.jpg)

.jpg)

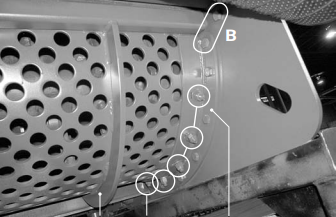

The sizing screen is a critical component in our engine drive machines, designed to regulate the final material output size.

It functions by filtering shredded material, ensuring only appropriately sized pieces exit the machine while larger fragments

are retained for further processing.

The EDS sizing screen ensures a fine and uniform processing (shred size is consistent). The EDS sizing screen is made out of durable material

and is easily replaceable, reducing down time and easing maintenance costs

The FLMB400 / FLMB400E are a double row spherical expansion bearing. These bearings are designed to handle angular misalignment, ensuring smooth operation even if the shaft or housing is not perfectly aligned. This feature reduces the risk of premature wear or failure. Double-row spherical roller bearings can carry both radial and axial loads simultaneously, making them ideal for heavy-duty applications such as brush shredding. As an expansion bearing, small amounts of shaft movement is allowed due axial loading (common in brush shredding) preventing excessive bearing stress and increasing bearing longevity.

.png)

The Hydraulic feed rolls are an essential component in the EDS shredders, designed to efficiently guide material

into the shredding system while providing precise control over feeding speed and pressure. They play a key role in

optimizing processing efficiency and ensuring uniform material intake.

Key Features and Benefits:

- Controlled Material Intake:

The hydraulic feed rolls regulate the flow of brush and debris

into the shredding chamber, preventing overloads and ensuring consistent processing.

- Independent Speed Adjustments:

Operators can control the speed of the feed rolls based on the

material density, allowing for higher torque in heavy brush conditions and increased speed for lighter material.

- Reversible Rotation:

The ability to reverse the feed roll direction helps clear jams and improve shredding efficiency.

- Height Adjustability:

The top feed roll can be raised or lowered hydraulically to accommodate varying brush sizes and

optimize material contact.

- Hydraulic Power System:

Powered by an open-center hydraulic circuit, the feed rolls deliver steady torque and responsiveness,

ensuring smooth operation.

- Enhanced Shred Quality:

By maintaining a consistent feed rate, hydraulic feed rolls help improve shred uniformity and maximize

processing effectiveness.

The Flexxaire Reversing fan assists with keeping the engine cool. This fan periodically revereses to help keep the engine & compartment clean, thus reducing maintenance costs.

| Specification | |||

|---|---|---|---|

| Cutting Width | 9' | ||

| Overall Width |

136" Width 240" Pintle to Bumper |

||

| Hitch | 3-Pt Pintle Hitch 49,000 lb Rated Pintle Pivot Located for Minimum Turn Radius |

||

| Tractor Requirements | Approximately 80HP Engine (2) sets of Hydraulic Remotes for Operating Axle Lift & Top Feed Roll Height Adjustments (4) Wheel Drive, Fully Weighted Front End |

||

| Hammer Type | FL8041TA4 | ||

| Rotor Mandrel | 2-7/16" Replaceable Bolt-On Shafts Mandrel:8-5/8", 7/8" Wall |

||

| Mandrel Speed | 2,000 RPM | ||

| Blade Tip Speed | 13,624 fpm | ||

| Weight, STD. Unit (Opt. Dependent) | Axle Weight: 17,000lbs Tongue Weight: 1,350lbs Shipping Weight: 26,000lbs |

||

| Engine | JD 6090 Power Tech Engine:

400 HP Tier IV, Turbo Charged 16.5 GPH Fuel Consumption @ 85% Power Consumption |

||

| Belt Drive | Dual Drive: 6-Groove, 6VK Kevlar Cord Belt Drive with Auto-Tensioning System |

||

| Tires | 21.5X16.1 14PR Forestry Tires | ||