The ASH shredders are versatile pull-type PTO brush shredders, designed for efficient brush processing.

Featuring a rigid bumped housing, these units excel in handling tough materials. Each shredder comes

equipped with a replaceable inner housing liner and shear teeth for long-lasting functionality.

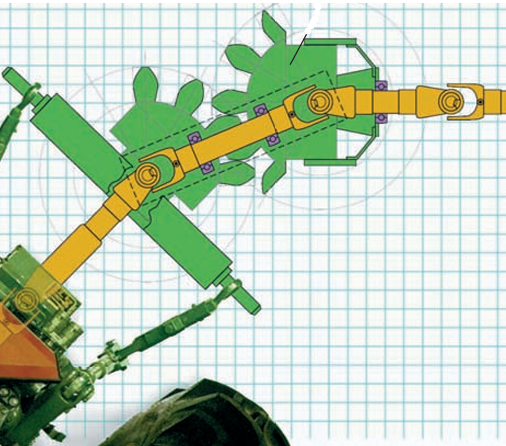

The CV hitch 3-point attachment ensures smooth power transfer from your tractor to the drive train while

turning. Rear floating rake teeth help to feed material into the rotor swing-line, and help to retain material

for a superior shred quality.

The ASH model may be fitted with FL8041 tungsten carbide hard-faced hammers for maximum durability when brush shredding or FL8021

long crop-chop knives for shredding more fibrous materials. Available options include the fine shred kit (more rakes, more interferences, brush

inlet guides), single or dual rear tire struts, a heavy duty welded axle, tighter rake spacings, and dual-drive vs. single drive setup.

Available cutting swath widths ranging from 5 to 10 feet.

The FL8021 Crop-Chop knife is ideal for shredding up more fibrous material (such as date palms) than the FL8041TA. These blades will also be able to mow while the shredder is not ideal for mowing grass.

The ASH / LSH / AHD Shredders come standard with single floating rake teeth

on 12" centers. These rake teeth help to maintain a constant relationship with

the blade swing, even over uneven terrain. This tight and consistent tolerenace

helps to achieve better feeding, shred quality, and eliminates brush buildup

on the rakes. Rake spacing may be narrowed to 9" spacing for an up charge

for the additional rakes.

The 9" rake spacing is common for citrus applications where very fine

shred quality is not as vital. In pistchios, walnuts, and pecans the fine shred kit

with triple fork rakes is recommended (Please see Fine Shred Kit option below)

The FLMB400 / FLMB400E are a double row spherical expansion bearing. These bearings are designed to handle angular misalignment, ensuring smooth operation even if the shaft or housing is not perfectly aligned. This feature reduces the risk of premature wear or failure. Double-row spherical roller bearings can carry both radial and axial loads simultaneously, making them ideal for heavy-duty applications such as brush shredding. As an expansion bearing, small amounts of shaft movement is allowed due axial loading (common in brush shredding) preventing excessive bearing stress and increasing bearing longevity.

.png)

Rears Shredders utilize our Constant Velocity Hitch

for superior tracking: keep on running through 90° turns. Telescoping driveline eliminated protects tractor PTO

Utilizes the tractor 3-point hitch removes the requirement to establish a hitch pin center point

Our Constant Velocity Hitch offers several advantages over a CV Driveline:

Smooth Power Transfer: It ensures uniform rotational speed, even when the tractor and

implement are at different angles, reducing vibrations and noise.

Flexibility: It allows for efficient operation during sharp turns or uneven terrain,

maintaining consistent performance.

Durability: These hitches are designed to handle high torque loads and are very robust. CV hitches

do NOT utilize a CV driveline (which may be expensive and difficult to maintain).

Reduced Wear and Tear: By minimizing vibrations and shocks, it helps extend the lifespan of connected machinery.

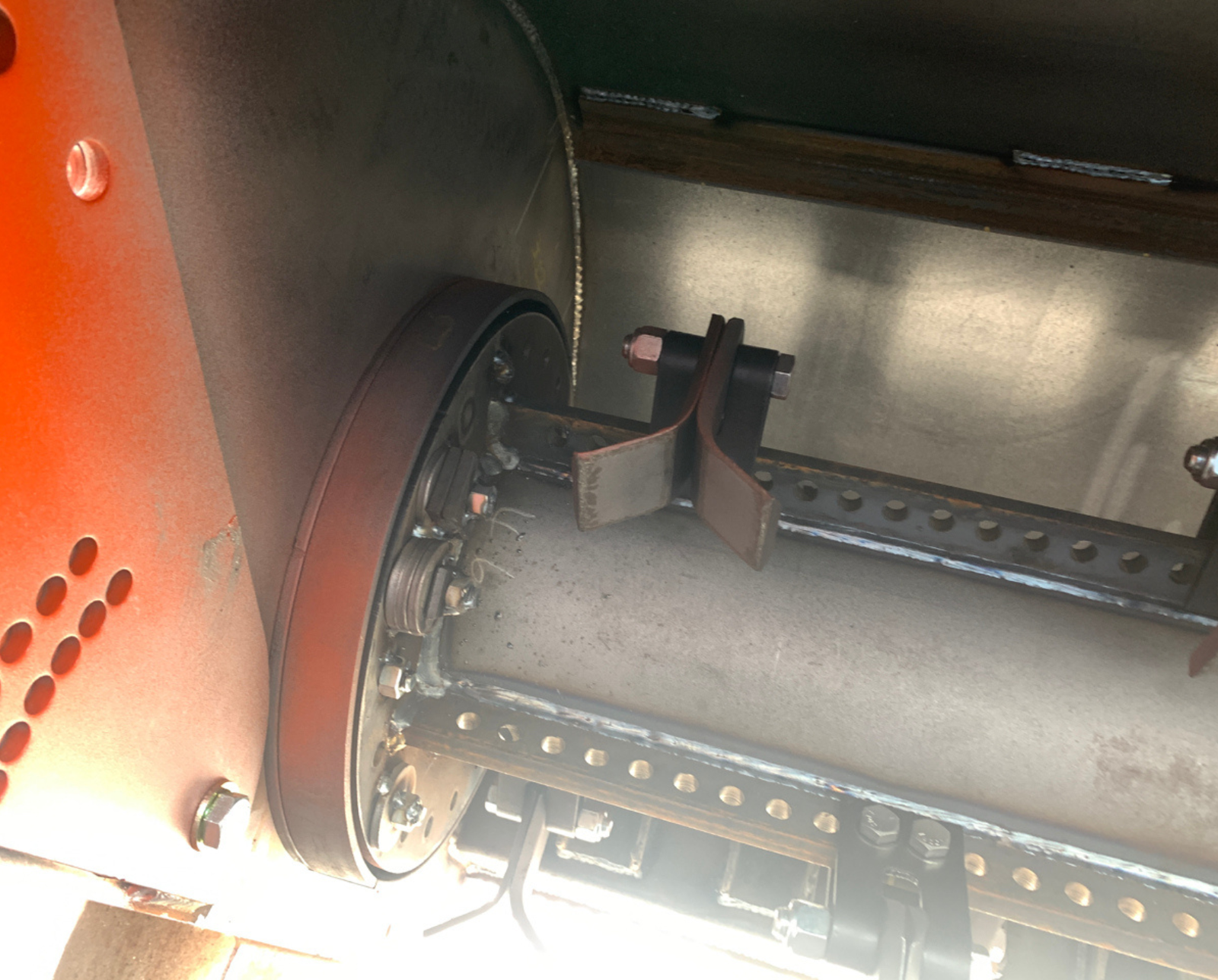

As seen in the picture to the right, the standard ASH / LSH axle utilizes clamp on struts. These struts may either

be dual struts or single struts (dual struts is standard on 9' & 10' units, is an option on 5'-8').

This option is standard and works well for small to mid-size growers (150-300 Acres). The clamp on struts tend to wear and

crack over time as the bolts become loose and the struts are allowed to shake on the pipe. For larger operations or growers

aiming to avoid future axle repairs, the heavy-duty welded axle is recommended. Notably, this axle, along with dual struts,

is included as standard with the fine shred kit.

The heavy-duty welded axle, standard on 9' and 10' units, replaces the traditional clamp-on dual struts with welded-on struts. This design significantly reduces maintenance requirements and has been highly effective for users who opt for it. Rears strongly recommends the heavy-duty welded axle whenever feasible for enhanced reliability and performance.

.jpg)

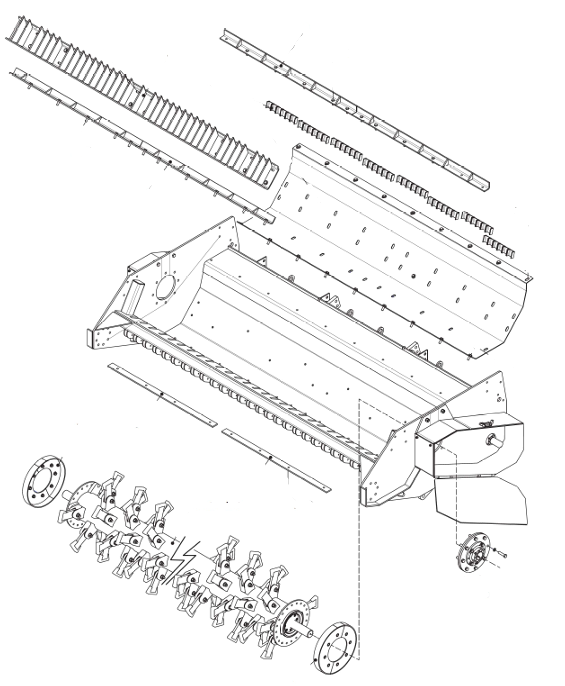

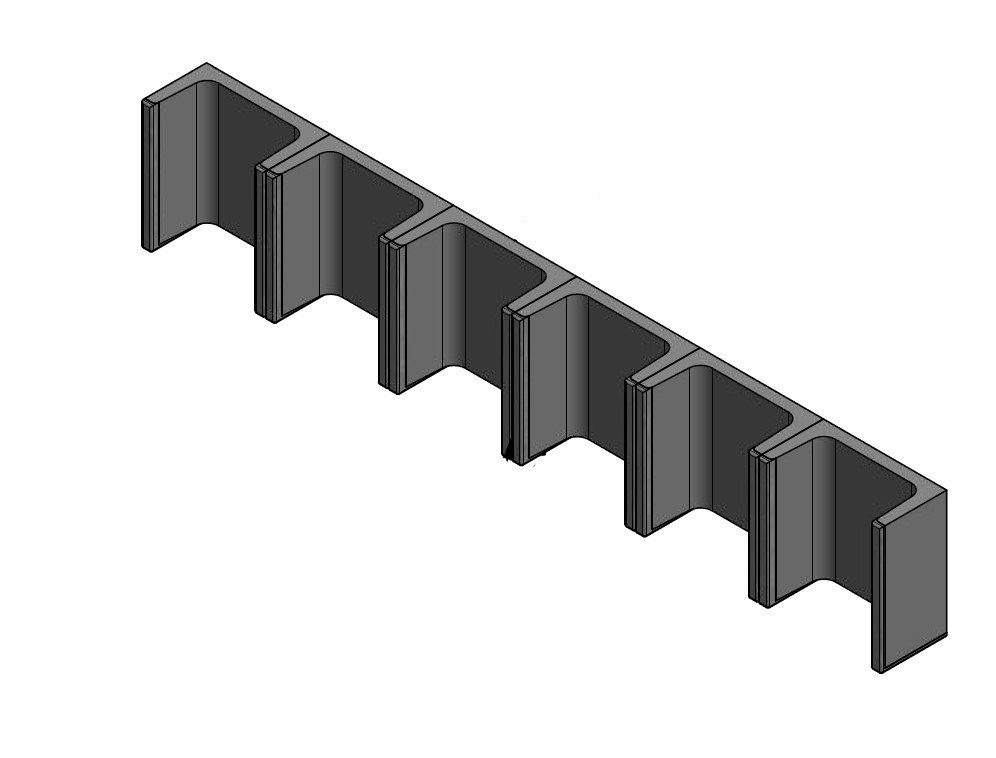

All pulshredders (ASH, LSH, and AHD models) come equipped with a channel shearbar that e nhances brush shredding efficiency. The spinning rotor works by feeding the material into the shear channels, where it is shattered effectively. The channel shearbar is designed with very tight tolerances between the hammer and the sides of the shear channel, ensuring precise shredding and superior quality results. The channel shearbar is bolted into the housing and can be replaced.

All pulshredders (ASH, LSH, and AHD models) are equipped with at least one angle shearbar, which plays a critical role in pulverizing brush. Material is directed along the swing line and crushed against the interference angle, assisting in effective shredding. Through extensive refinement over various iterations, the position of the shearbar in the housing and size of the angle shearbar have been optimized to deliver the highest possible shred quality. If the fine shred kit option is chosen, an additional angle shear bar will be added to the shredder. The angle shearbars are bolted into the housing and can be replaced relatively easily.

All pulshredders (ASH, LSH, and AHD models) are also equipped with a full width set of shear channels to increase shred quality even further. These channels provide a surface for material to shred against. Shear channels are hard surfaced for longevity and contribute significantly to increased overall material shred quality. These shear channels are welded to a replaceable liner which is bolted into the housing.

.jpg)

The fine shred kit is an enhancement option for the ASH Shredder that incorporates triple fork rakes with narrower rake spacing. This design minimizes coverage gaps and improves shred quality by efficiently guiding material into the rotor swing line, ensuring less material is missed during the shredding process. Additionally, the triple fork rakes aid in recycling larger prunings that were not fully shredded on the first pass, maintaining consistent and thorough processing.

The fine shred kit includes a number of different forms of interferences within the housing to assist with shred quality. Two angle shearbars, a channel shearbar, and a full length set of hard faced shear channels are installed in housing pulverize material. Liner, angle shearbars, and channel shearbars are all bolted in and replaceable.

The fine shred kit includes a set of front inlet guides to assist with guiding material into the flail housing. The brush inlet guides are also available as an add-on to machines not equipped with a fine shred kit (FSK).

| Specification | |||

|---|---|---|---|

| Cutting Width | 60" - 120" | ||

| Overall Width |

Single Drive: 16" Over Cutting Width Dual Drive: 20" Over Cutting Width |

||

| 3-PT | Category II Freelink Cat. II Standard, Cat III & Quick Hitch Compatibilty on Request |

||

| Horsepower Requirement | 10-15 Horsepower/ft Depending on Loading Scenarios (Ground Speed / Terrain / Biomass) |

||

| Hammer Type | FL8041 | FL8021 | |

| Rotor Mandrel | 2-7/16" Replaceable Bolt-On Shafts Mandrel:8-5/8" |

||

| Mandrel Speed | 2,050 RPM | ||

| Blade Tip Speed | 13,624 fpm | ||

| Weight, STD. Unit (Opt. Dependent) | 7': 6,000lbs 8' 6,200lbs 9': 6,400lbs Weight Depends Greatly on Options Chosen | ||

| Gearbox Rating | 85 Horsepower | ||

| Belt Drive | Single Drive: 5-Groove, 5VX Belt Drive | Dual Drive: 4-Groove, 5VX Belt Drive | |

| Flail Housing | 1/4" Mild Steel | ||

| Hydraulics | Requires one Set of Tractor Remotes | ||

| Input Driveline | Category VI | ||

| Cut Height | Scalping (0") - 6" | ||