The Rear's Cane Shredder is equipped with a hydraulic feed roll that guides material into the flail housing, where it is shredded by our hard-faced OM750 hammers. The cane shredder efficiently cuts vines, holding them in the housing until they're sufficiently reduced to pass through the sizing screen. Engineered for maximum cutting coverage, this machine minimizes additional width, making it ideal for use in vineyard and berry rows. The cane shredder sizing screen drastically increases horsepower requirements. Rears recommends a minimum of 10-15 horsepower/ft at the tractor PTO to effectively run this machine.

The OM750 hammer is Specifically Designed for Shredding Brush. This hammer type (in conjunction with the cane shredder sizing screen) efficiently grinds material up.

The hydraulic motor chain drive feed roll helps to lift and feed material into the housing for increased coverage and better shred quality.

The OMMB100 is a double row spherical roller bearing. The capability for these bearings to handle radial and axial loads combined with their acceptional durability and self-aligning design make them ideal for demanding environments.

The cane shredder sizing screen ensures that material has reached an acceptable shred quality prior to leaving the housing. The sizing screen increases horsepower requirements, but also does an excellent job of ensuring that brush is mulched to an acceptable level.

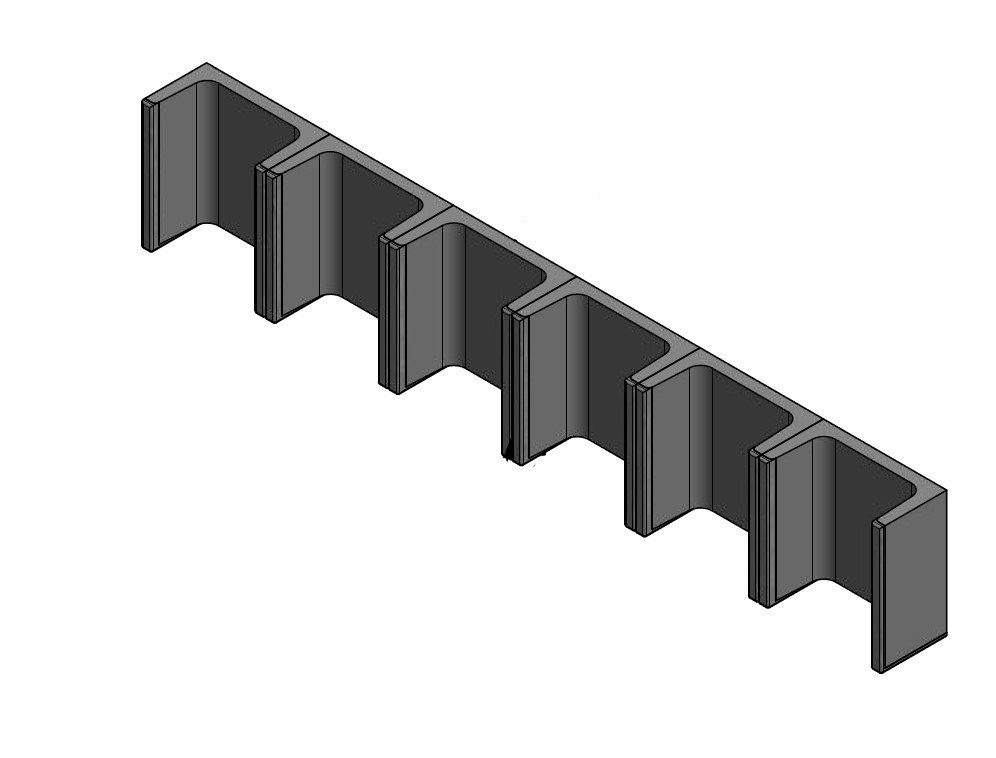

As seen in the video at the top of the page, brush has the ability to go around the endplates. For this reason, the engineers at Rears Manufacturing developed these brush inlet guides to help feed material into the cane shredder hydraulic feed roll system.

In addition to the sizing screen, the cane shredder utilizes a weld-in angle shearbar to further increase shred quality.

.jpg)

Bolt-on fixed struts with heavy duty 23x8.50-12 loader lug tires allow for durable and user friendly cut height adjustment.

| Specification | |||

|---|---|---|---|

| Cutting Width | 48" - 72" | ||

| Overall Width | 8" Over Cutting Width | ||

| 3-PT | Category I & II Freelink Cat. I & II Standard Quick Hitch Compatibility on Request |

||

| Horsepower Requirement | 10-15 Horsepower/ft Depending on Loading Scenarios (Ground Speed / Terrain / Biomass) |

||

| Hammer Type | OM750 | ||

| Rotor Mandrel | 1-15/16" Shaft Mandrel:8-5/8" |

||

| Mandrel Speed | 2,100 RPM | ||

| Blade Tip Speed | 11,500 fpm | ||

| Weight, STD. Unit (Opt. Dependent) | 48": 2200lbs 60": 2300lbs 72": 2400lbs | ||

| Gearbox Rating | 85 Horsepower | ||

| Belt Drive | 3-Groove 5VX Belt Drive | ||

| Flail Housing | 1/4" Mild Steel | ||

| Hydraulics | Requires one Set of Tractor Remotes | ||

| Input Driveline | Category VI | ||

| Chain Drive | Double Strand 60 Chain | ||