The Rears Sanitation Mower is an essential part of any sanitation regiment for your orchard. This mower features an extended front shelf with a

chain guard, and a PTO drive system for the mower and accessory blower (blower and sweeper are optional add-ons). This mower has three forms of

interference in the housing in addition to a rear recycling door to ensure that leaves, sticks, and nut shells are picked up and pulverized.

Constructed with durable A36 steel, this machine comes standard with a bolt-in liner for added durability. Key shredding components include a

rear recycling door, two angle shear bars, shear channels, and durafaced 946 crop-chop mounted at 6 assemblies per foot instead of the usual

4. These blades are operating at a tip speed of 12,520 FPM, enabling blades to pass over shear bars and channels 33 times per second to ensure

adequate shred quality is achieved.

Dual sided mechanical berm blower and sweepers are available to ensure that mummies and foliage are either swept into the housing or blown into

the next row so that they can be shred on the next pass.

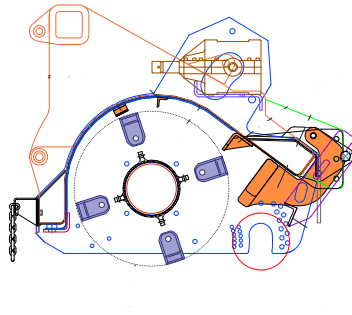

Drive system and rotor highlights:

Standard on our field choppers, the crop-chop knife is rolled to shape from C1050 alloy steel and heat treated for long edge life. Both the FL940 and 946 are reversible- the FL946 is a hard surfaced knife. Unlike our standard mowers, the sanitation mower has these blades mounted at 6 assemblies per foot. This is 1-1/2 times the usual blade coverage.

The Sanitation Mower is equipped with a recycling door, shear channels, and two angle shearbars that assist with with increased shred quality.

The Sanitation Mower is equipped with a number of weapons to help pickup and shred leaves, sticks, and nut shells (mummies). The recycling door is the star of the show, helping to keep material in the housing until it has reached a certain shred quality. The restriction of the flail discharge helps to increase the number of hits that the leaves/mummies recieve, resulting in a higher probability that they will be destroyed. The recycling door is also coupled to a roller scraper, which helps to prevent excessive mud buildup on the roller.

The sanitation mower is equipped with two angle shearbars for material to slam against. These hits result in shattering of nuts / sticks.

Hard surfaced shear channels are welded to replaceable liner (full length of flail) to allow material to be efficently ground up against the hardened surfaces.

.jpg)

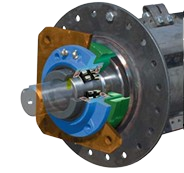

Our self-aligning double spherical FLMB500 roller bearing is a top-tier performer, specifically designed for handling heavy loads and impact deflection.

This rotor bearing demonstrates unmatched durability and reliability.

To protect the bearing from the harsh environment inside the flail, the engineers at Rears developed an integrated grease

labyrinth barrier within the rotor mandrel. This barrier provides maximum protection and effectively isolates the bearing.

The design ensures that over-greasing is no longer a concern, as all excess lubricant is vented into the renewable labyrinth, thus purging

any impurities that have been introduced during operation. This grease labyrinth also helps to keep the bearing cool under load.

24" centrifugal fan with remote control, dual outlets, and cable-controlled baffles. Allows single-side or dual-side operation, and can be disengaged for flail-only functionality. Hydraulic and electrically actuated air gates (on/off for left/right blower operation) are available upon request.

Flail Mounted dual-sided or single sided sweepers are available as an add-on for the sanitation mower.

Sweepers are available in two sizes: 46" diameter or 32" diameter. This, combined with choosing the correct flail

width, can ensure that the sanitation mower/sweeper/blower combo may be properly sized for your orchard.

Sweepers can be front tractor mounted as well. Sweepers are run in series and therefore require only one tractor

remote. Our sweepers have extensive ability to expand out or in as well as adjust the angle of attack to ensure that

the sweeper can be set up to your orchard needs.

| Specification | |||

|---|---|---|---|

| Cutting Width | 8' - 12' | ||

| Overall Width | 12" Over Cutting Width | ||

| 3-PT | Category II Freelink Cat. II Standard, Cat II Quick Hitch Compatibilty on Request |

||

| Horsepower Requirement | 10-15 Horsepower/ft Depending on Loading Scenarios (Ground Speed / Terrain / Biomass) |

||

| Hammer Type | FL946 | ||

| Rotor Mandrel | 2-7/16" Mandrel:8-5/8" |

||

| Mandrel Speed | 1720RPM | ||

| Blade Tip Speed | Value Needed | ||

| Weight, STD. Unit (Opt. Dependent) | 4,000-5,200 lbs (8'-12') Weight Depends Greatly on Options Chosen | ||

| Gearbox Rating | 120 Horsepower | ||

| Belt Drive | 5-Groove, 5VX Belt Drive | ||

| Flail Housing | 3/16" Mild Steel Housing with A36 Bolt-in Liner | ||

| Hydraulics | Dependent on Options Chosen | ||

| Input Driveline | Category VI | ||

| Cut Height | Scalping (0") - 6" (Call if needed Outside Range) | ||